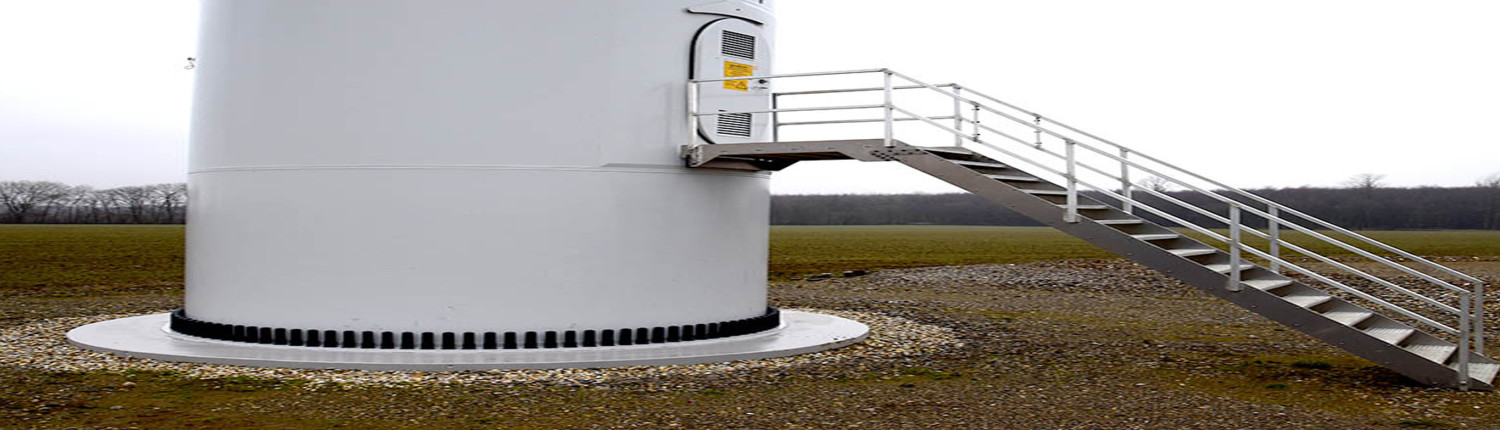

MOM Condition monitoring system for wind power plant foundations

In order to be able to run wind power plants in a safe and cost-effective fashion, they have to be built on a fully functional, durable and stable foundation.

However, reliable predictions of the strain on foundations by simulation have become near impossible. On the one hand, power plants are continuing to get larger and more powerful, on the other hand, environmental conditions and wind force fluctuations are becoming more and more extreme and hard to predict. It is extremely difficult to achieve the correct dimensioning of component parts according to real external loads and to predict component lifetime reliably.

Extreme conditions lead to increased wear; material fatigue often occurs sooner than predicted.

In order to avoid cost-intensive refurbishment measures, many independent surveyors and insurers recommend continuous monitoring during operation. This is the only way to detect the impact on the usability of the foundation early on.

The earlier in the lifecycle of a power plant that you begin with continuous monitoring of components that are under a lot of strain, the more reliable later detection of damage becomes. Particularly in areas of load application, early monitoring has proven to be an advantage. It can provide such exact predictions of maintenance procedures that power plants need not be shut off in the meantime, avoiding an unnecessary loss in earnings.

This minimizes technical and economical risks. Continuous condition monitoring is extremely cost effective, especially for highly strained components such as foundations.

MOM 8.4e Condition Monitoring Systems for wind power plants:

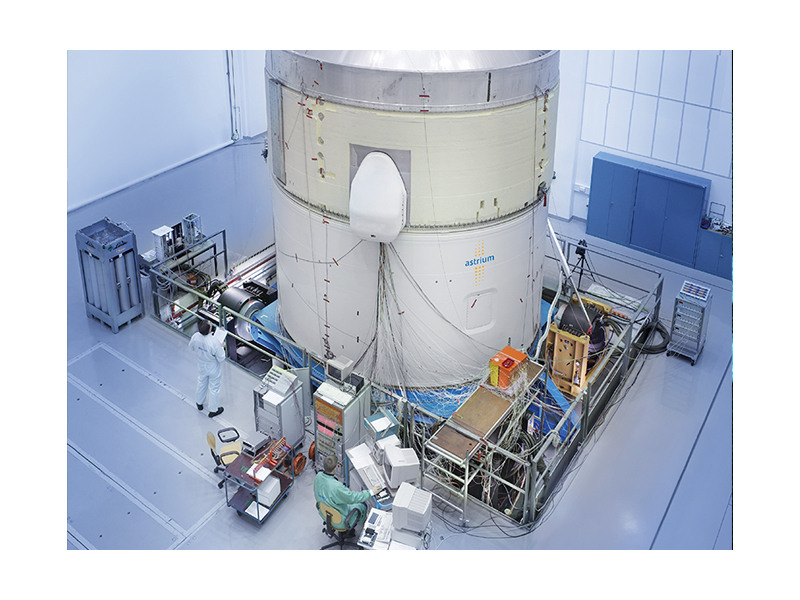

- Monitoring and data logger for continuous measuring of operations in order to record damage development (mainly in areas of load application)

- Load measurement of tower base clamps:

Measurement of the relative displacement between foundation and concrete (maximum local component load, especially on concrete)

- 8 channels including 3.3 V power supply for common sensors (meters)

- 4 temperature sensors -40 °C to +85 °C

- Dimensions only 165 x 46 x 100 mm

- Lithium-ion battery: 96 hours full load without external power supply

- Efficiency: external power supply 5V/1000mA

- Latest 32 Bit ARM processor architecture

- Internal data storage with 16-64 GB (data storage for one year of full load)

- Ethernet port for data export & network integration

- Online data via WOTSPOT® our browser interface for smartphone and tablet

- Optional connection via UMTS or live data visualization

Further information can also be found in the news section:

- Cost savings through condition based maintenance, Artikel der Markt & Technik 38/ 2014

- Monitoring of components with MOM C-M-S, Bericht in der Zeitschrift Konstruktionspraxis vom 27.06.14

more products of GEPA: